When shopping for a custom bag, t-shirts, or tablecloths, you may have noticed several printing designs that look attractive. However, one thing that may interest you is that in as much as all designs look the same they may have undergone different printing processes, like heat transfer printing, screen printing, and a few more methods.

There are a few key differences between heat transfer and screen printing. In heat transfer, an artwork is first printed onto a transfer paper using a sublimation printer. Then, that paper is placed onto the garment and heat pressed to transfer the design. This method is great for small runs or complex designs.

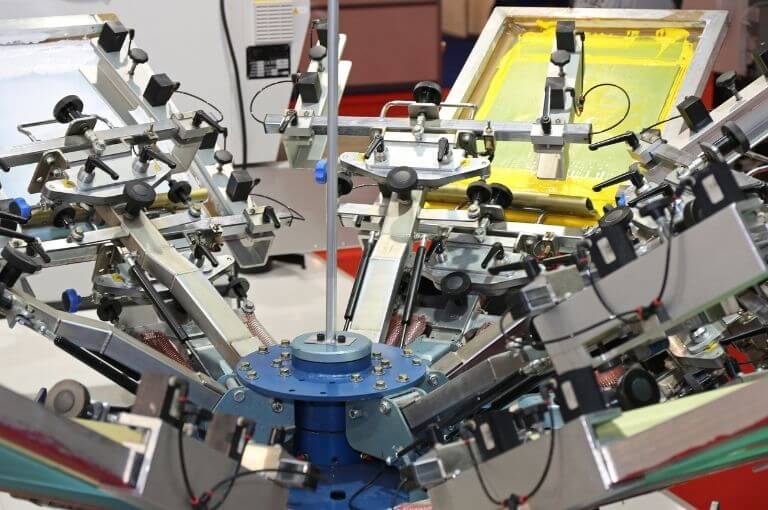

On the other hand, screen printing involves creating a stencil of the design and then using that stencil to apply ink to the garment. This method is better for larger runs and simpler designs. Screen print can be done by hand or with a machine.

The most common and popular printing options that are available are heat transfer and screen printing. In this article, we will discuss and guide you on what is the difference between them and what is the best printing process.

Screen Printing

When a printing design is done through the screen printing method means that a screen is cut to make a stencil for the design.

The ink is later on spread over the screen, and this allows the ink to spread only on areas that you want it to be.

In most cases, you can use one color per screen. However, the number of colors that you have determines the number of screens you need to get the final design.

Pros

- Very durable printing method, your prints will last for a long.

- Screen printing is a relatively simple printing method, making it a great choice for beginners.

- Ideal for printing large quantities of prints, as it is a very efficient printing method.

- Produces high-quality prints with rich, vibrant colors.

Cons

- The initial set-up cost can be relatively high, depending on the complexity of the design.

- In some cases, It can be difficult to get a consistent print.

- It can be difficult to print on dark fabrics.

- The screen printing process can be expensive for small quantity print.

- Screen print often requires the use of harsh chemicals and solvents, which can be dangerous to both the printer and the environment.

- Screenprint can be a very slow process, especially when compared to other printing methods.

Heat Transfer

The heat transfer process uses a custom design for t-shirts or tablecloths by using a combination of both heat and pressure. The common printing method that uses heat transfer includes a vinyl heat transfer and a digital print heat transfer.

The vinyl heat transfer uses a machine to cut the screen-printing designs and some colored vinyl. Then use a heat press to transfer the color design on the fabric.

On the other hand, the digital heat transfer uses a graphic that is printed on solvent ink. The ink is what makes it possible to transfer the design to a paper and then to the fabric.

These two types of heat transfer need a heat press machine to transfer the graphic from the vinyl or digital printing (DTG printing) design to the fabric. All the designs move by transfer when heat and pressure are combined.

Pros

- The process is quick and easy, and the results are professional-looking.

- The prints produced by heat transfer printing are of high quality.

- Heat transfer is a versatile printing method that can be used on a variety of substrates, including paper, fabric, metal, and glass.

- This is a cost-effective printing method, especially for small number print out.

- Perfect for creating unique, one-of-a-kind designs.

Cons

- It can be a slow process when comes to big numbers to print.

- Special equipment is required.

- The print can peel or fade over time.

- Another downside is that it can be difficult to get the colors to match up perfectly, especially if you are trying to print on a dark fabric.

Heat Transfer vs Screen Printing: At a glance

| Topic | Heat Transfer | Screen Printing |

|---|---|---|

| Definition | Heat transfer is an advanced process that allows us to direct the application of images and logos onto fabrics of various types. | Screen printing is a screen printing method of printing designs onto fabrics by using artwork, screen, frame, mesh, squeegee, ink, and a few more materials. |

| Durability | Durable but comparatively less. | In long run it’s durable. |

| Detail and color quality | The best output quality of print with more details. | Comparatively less detailed output but enough bright and clear print. |

| Print color fadedness | HT prints are more quickly fadable. because it’s print-only pressed on the surface of fabrics. | In screen printing ink goes through the yarn to yarn because of ink soaking. So SP has less fadedness. |

| How many times you can wash | It depends on many factors but it’s up to 50 washes. | Screen printing design lasts for a long time. It’s almost the lifetime of the clothes fabrics. |

| Expense | Less expensive in small numbers but bulk production is costly. | Initially costly the HT process but in long run for big numbers of the same design it much cheaper process. |

| Run Time | Only a few seconds (30-90 sec.) are needed to heat press but the whole process may take a few minutes. | Rund time for screen print is a concerning factor. The process needs more time than any heat transfer method. |

| Print softness | Print ink only stays on the surface of a fabric, so it’s a little bit harder. | Its printed area of clothes is softer than the HT process. |

| Best for | Best for small homes or garage-based businesses. | Best for big businesses with big numbers of production capacity. |

Which Printing Design is good for you?

The type of printing you choose depends on the type of material and the total number of items you have in the production line. Every unique design needs to be cut for different color use in screen-printing, this sounds to be cost-effective and suitable for large-scale production.

On the other hand, the heat transfer process uses the same approach with every print made, so making the initial design does not cost so much on your investment.

When to Use Screen Printing?

Most custom-made garment prints use screen-printing because of the many advantages though with some limitations. Screen printing should take place in a dedicated room because it takes a lot of time to complete.

Screen-printing involves the creation of the artwork, exposing the screen, laying down and curing prints, and setting the press. All these stages require a lot of labor and time.

Because of the intensity of labor and equipment, used screen-printing has a limitation that is expensive when printing in small batches. Nevertheless, here are some scenarios in that you can use screen-printing:

Printing on a large scale

A large printing press has to be made in the most cost-effective method compared to the heat transfer process. In general, screen-printing is cost-effective when the press runs do not go beyond 100 units to print.

Printing for special effects

Whether you want to apply filter or glitter, use puff ink or create a photorealistic image, or images that go beyond the basics of screen-printing

Printing vibrant or dark colors

In most cases, heat transfers in bright or dark colors do not come out well and are prone to fading over time.

When you need soft printing

Using heat transfer is heavy and uses many plastics in the process. For a soft feel on the prints, you need to rely on screen printing.

When to Use Heat Transfer?

Heat transfer is achieved in several ways; by the use of a screen printing press to generate heat. You can use this printing technique to create small batches using a vinyl cutter or inkjet printer to enable a quick heat transfer at a reduced cost.

However, some printers prefer to use heat transfers when they have printing jobs in small batches.

The limitation to heat transfer is their labor intensity, and the time it takes when handling large printing jobs. Depending on your preferred method of transfer, you may end up with colors that are not as bright as you would expect.

Heat transfers tend to break faster than screen prints. However, heat transfers are appropriate in the following circumstances:

Printing in small batches

Heat transfer offers so many capabilities that can help turn small print jobs profitable with minimal effort.

Personalization of fabric

You can print player jerseys by printing a name or number.

Print on oddly shaped materials

Printing on items such as bags, caps, and any other item with a unique shape is a challenge. With heat transfer, process printing on such surfaces now becomes an easy undertaking.

Quick printing

If you need print materials that are appropriate for events, concerts, and festivals, using heat transfer is the best option. You can pre-cut or print the artwork and apply heat transfer using a small heating press.

The Debate Ends

We can carry on with this debate, but it is up to you as a printer to look at the prevailing conditions and the materials you have to get the best printing technique that will enhance productivity and profitability.

Read More Article On:

How to shrink polyester – the best way