DTG refers to ‘Direct To Garments’ which means to print directly on textile garments. On the other hand, screen printing is one of the most popular uses for printing in the world, which can be done on your fabric at a low cost in any situation.

If you want to start a successful simple business then garments printing is a good option for you. There are several steps in screen printing that you can add for printing, but digital printing (DTG) saves a lot of time.

DTG and screen printing are related to printing technology to be directly profitable from the first step of manufacturing. Direct to garments (DTG) will give you quality and time allowance while screen printing will give you the best risk-avoiding factor with experience hand.

If you suffer from confusion between DTG and screen printing, whichever you prefer will help you to grow your business profitably, this article is for you.

In this DTG vs Screen printing article, we will learn more about DTG and the production of screen printing. In the end, it is up to you to decide which of these two is most profitable for you.

Let’s get started.

DTG vs Screen printing: At a glance

| DTG printing method | Screen printing method |

|---|---|

| The DTG (direct to garment) printing process uses specialized custom printers that use special ink and follow the directions of computers to create images or text on clothes. | Screen printing is an early age method of printing with a design on the mesh material. The mesh is stretched on a frame or table, and ink is forced through the mesh onto the substrate to print. |

| DTG printing is a newer method. | Screen printing is an old printing method comparatively. |

| Able to do more precise and detailed printing. | Compared to DTG less precise and detailed. But still, print very high-quality images. |

| DTG output paint is more sustainable. | Less sustainable comparatively. |

| No minimum quantity issue with costing. | More suited for a larger amount of printing in terms of const effectivity. |

| DTG offers unlimited color with no limitation on colors number. | Limited numbers of colors can be used at a time compared to DTG. |

| On-demand fulfillment is possible. Speedy process. | Needs more setup and first start time. |

| More cost-effective. | Comparatively costly, especially for small numbers of printing cases. |

| Need a few numbers of labor, even for bulk production. | It needs more labor. |

In my opinion, if you want to know which is the winner? then, it’s DTG. But it mainly depends on many different factors.

Nowadays, the customer wants fast delivery with possible best and most durable quality. And business wants profit, so they need high-quality output at a low cost to maximize profit. Considering all of these DTG has an age over screen printing. But again still you need to think about your position and your environment. So read this full article before you settle for one.

How DTG printing works

Director to Garments Printing is a type of printing that is done by spraying on fabrics or garments. Whenever you are given clothes on a painting machine for printing inside the machine, the inks are used like many paintbrushes to create a direct drawing on the clothes.

With the help of this, it is possible to make any kind of design directly.

The biggest advantage of DTG printing is that it time-consuming time is much more. For instance, you run an online business where you can select only the design that your customer likes and print it directly on the fabric.

First, place your design on the DTC machine software that is installed on your computer. After confirming the design, edit there and bring out the original image using various software. Multi-color and highlighting this image will be placed on your conscience garments.

The key factor is that once you decided to put it on, it will print from your design on your T-shirt or on the garment fabric in a short time.

At the bottom of the DTG machine printer, there is a place to keep the cloth. Put the part of the garment on that part of the machine. Now with the command of the machine, the design from the printed fabric software will be printed on your garment and gently in front of the machine. In case it comes out side by side; you have to make sure that you get enough temperature and time to dry after printing.

DTG printing factors (Advantage & Disadvantage)

DTG advantage over screen printing

In the case of printing, the cost of your production decreases when you print more, but in that case, the digital machine is a bit of an exception. Here you can make love to your customer with a T-shirt of multi-color.

Even if you want to use bulk the proportion of your production post will be reduced at the same rate but it is quite expensive as compared to screen printing.

Digital printing machines have gained considerable popularity in modern times. Needs no investment in paper or screens; only matching printers have been used to increase the collaboration for building different colors directly on top of garments.

One of the advantages of digital printing is that you can print it on any kind of knit garment or woven fabric garment. This ink penetrating ability is excellent, so it can be inserted directly on the garments of the front part and suit like paint.

DTG disadvantage compared to screen printing

There is a considerable cost involved in the use of electricity and machinery. The cost of digital printing is definitely higher than that of screen printing because the multipurpose mechanism used is quite expensive.

Many people avoid using a DTG machine due to a lack of efficiency and handling experience.

For DTG printing, it is essential to have an uninterruptible electric supply and an adequate amount of ink inside the machine.

Its machine handling is quite risky without the expertise of DTG printing.

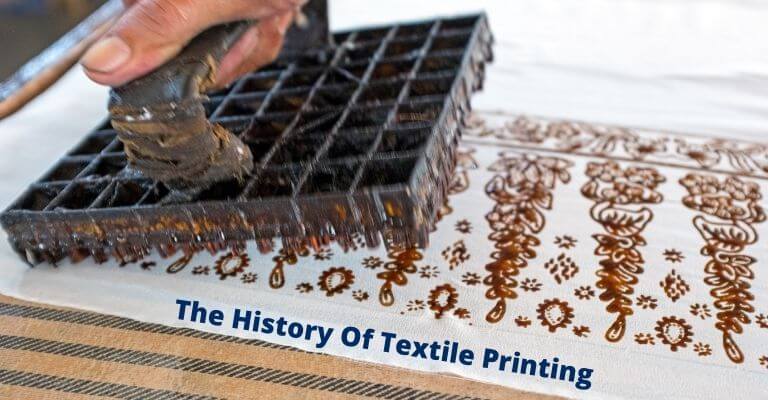

How screen printing works

Screen printing is the type of printing technique that is most commonly used to print on top of your fabric by transferring ink onto fabric by using a mesh stencil. Silkscreen printing is therefore quite popular in the traditional sense.

When it comes to screen printing, this is the most widely used printing method.

After the selection of designs, screen printing is done on the basis of by creating different patterns in different steps. Each time different frames are given different colors and designs are given one after another.

Films made for a variety of bulk productions are often time-saving and financially profitable.

The amount of water used in screen printing is slightly higher than that of other chemicals and the plastisol ink used is not harmful to garments.

Screen printing factors (Advantages and disadvantages)

Screen printing advantages the DTG method of printing

There is no pair of screen printing for doing profitable business in line with the requirements for bulk production.

With the help of printing, it is possible to make many fabrics together by coloring them on different screens and mesh. You have to keep in mind that screen printing is a very profitable way to do business in bulk quantity of industrial production.

Separation can be done for ink and coloring. Screen printing is very good for white and black colors. With the help of this, you can produce more at a low cost. Know more here to calculate the estimated cost for screen printing.

Screen printing disadvantage compared to DTG

When it comes to disadvantage factors, usually time fact comes first to be brought forward.

In many cases, a design has 6 to 7 multicolors. All the colors have to be embedded in the same design. Different mesh and frames of screen printing with different designs part have to be created.

This is quite time-consuming and expensive as the previous design has to be dried before each installation.

With DTG digital printing we can have almost all types of designs and colors but in many cases; it is not possible to get the detailed design of screen printing.

Which one you should choose for business?

The first step in doing business is to keep in mind your customer and the buyer. If your production requirements are like this and a certain amount of profit can come then you can consider any one of the printing machines.

But at the beginning used only as your own production factory. You need to keep in mind that the sustainability of a DTG printing machine is much more than screen printing. You can do this with the help of a machine and that is what you need to do to increase your customer’s belief in you.

So, I would say that in the beginning screen printing method and its knowledge is well assed than in the test leading to a digital machine.

Also when you become an expert in DTG machines and know screen printing from convention then you can handle your buyer different way. This is how a successful business needs it.

You decide which one will make your profile better with sustainable profit. When you see your business moving forward and will continue to grow your business by considering any sustainable method.

Final words

This age of modernization is randomly moving towards digital. Even though we no longer use screen printing machines as we did 30 years ago, we don’t do screen printing in the same way. Today’s chemicals are more eco-friendly than they used to be for industrial purposes.

We all know the importance of our raw materials and eco-friendly equipment for establishing a business. In the business case, it is possible to earn money by using it. Screen printing is seen in many cases, so, you can do your business with the help of machines.

I hope this comparing article helped you to improve your knowledge of the DTG & screen printing machine’s production, advantages and disadvantages.